EOR and Shear Connection Design of Steel Buildings

This blog entry addresses engineering, detailing, and erection of shear connections which represent 95% of the connections on every steel project. While they are often unfairly regarded as simple, they are rarely simple. Shear connections are complex due to the many different types of connections, number of limit states to check, as well as geometry and erection complexity. I will compare and rate the various methods the Engineer of Record (EOR) uses to provide shear demands. In addition, common types of shear connections will be presented and discussed. Shear connections are rarely controlled simply by the number and capacity of the bolts, and this paper will examine all limit states and discuss what to look out for during shop drawing review. There has been an ongoing debate as to the responsibility for the design of steel connections for building projects. As a result, different practices are used in design office varying across the country. For instance, on the west coast, the connections are often fully designed by be EOR as part of the construction documentations. Whereas, on the East coast, the connection design criteria and requirements are specified on the construction documents, but the final design is delegated to a licensed professional engineer (often hired by the fabricator) in the state of jurisdiction. I have the rather unique experience of seeing both sides of the issue of connections design, first as an EOR designing buildings, specifying connection criteria and checking the shop drawings for conformance. And now for the past four years, I have worked for fabricators to design connections based on the requirements specified by the EOR. It through seeing this issue from both sides, that I have an appreciation for the importance of the proper attention to shear connection design.

The 2010 edition of the AISC Code of Standard Practice outlines three options for the responsibility of the connection design. It presents a new (albeit already established and widely used) third option where by the EOR delegates the connection design to a professional engineer hired by the fabricator. This article is not a review of these options, but rather a presentation of the various practices used by the EOR to specify the shear connection requirements as seen by the author in review of hundreds of Construction Documents. It is the hope that it becomes clear that this new third option should become the industry standard for all connections including simple shear connections.

Why Every Shear Connection Must be Checked

Most often, at least on the East Coast, the steel connection design is relegated to the fabricator and the EOR provides demand criteria and typical details for the design of the connections. The fabricator either has an in house engineer or hires a connection engineer to design the connections (typically the shear, moment and bracing connections). .

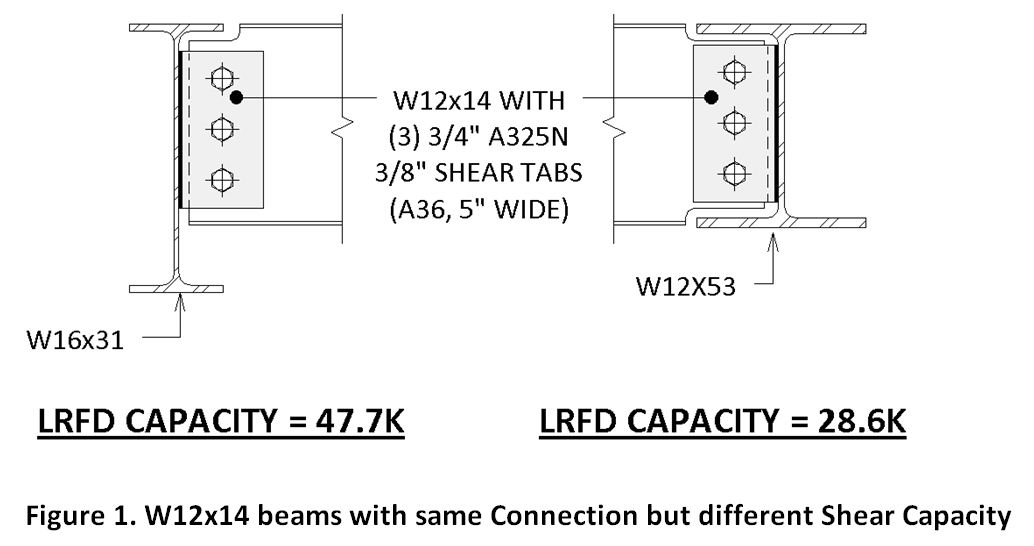

However, in some cases the EOR does not always require the shear connections to be designed by an engineer, only the moment and bracing connections. This is a mistake. While shear connections are perceived as simple, they often are not. Take for instance the most common type of shear connection - the beam-to-beam connection, which is actually pretty complicated. As is commonly known, all beam-to-beam shear connections have a top cope, which can make the design tricky. In addition, the cope varies based on the size of the girder – so it is not uncommon for the same size beams with the same type of connection material (shear tabs, bolts, etc) will have very different capacities. For example, a W12x14 framing into a W16x31 has a very different capacity than a W12x14 framing into a W12x53 even if the shear connection is identical, see Figure 1.

Not only is the W12x14 double coped when framed into the W12x53, but the copes are larger (both deeper and wider due to the thicker and wider girder flange) in comparison with the W12x14 framing into the W16x31. The reduced section due to the large copes significantly decreases the shear capacity of the connection by nearly half. Often times shear connections are not controlled by the bolt shear capacity (especially light beams with double angle shear connections). They may be controlled by bolt bearing, shear rupture of the web, block shear capacity of the web or coped section capacity. In the following sections we will explore the various ways the engineer of record specifies shear demands in addition to clarifying the different shear connection types.

Not only is the W12x14 double coped when framed into the W12x53, but the copes are larger (both deeper and wider due to the thicker and wider girder flange) in comparison with the W12x14 framing into the W16x31. The reduced section due to the large copes significantly decreases the shear capacity of the connection by nearly half. Often times shear connections are not controlled by the bolt shear capacity (especially light beams with double angle shear connections). They may be controlled by bolt bearing, shear rupture of the web, block shear capacity of the web or coped section capacity. In the following sections we will explore the various ways the engineer of record specifies shear demands in addition to clarifying the different shear connection types.

EOR Methods of Providing Demands

There are a variety of methods that are used by engineers to provide the fabricator the shear demands for the design of shear connections, and based the author's experience, some are good and some should be avoided.

Method 1: Provide Actual Shears on Each Beam on the Plans

This method is when the EOR provides the actual shear on the plans for every beam. This provides a uniform reliability in all of the members and the most accurate and efficient connections result.

Method 2: Provide a Table of Shear Values

This is method can work but it may be overly conservative for some beams on the project if done improperly. The table on the left is too simplistic and greatly overestimates the shear demand on lighter sections. For example, a W18x35 will have the same demand as a W18x76. The author derived the right table based on the plastic modulus of the beam and studied each connection type and number of bolts required. The right table is a good one and feels free to use it on your project if appropriate. You can select the ASD or LRFD method, it really doesn’t matter.

Method 3: Shear demands based on Length of Beam

This is a very common method. It is provided in many different forms on the general notes but it is always based on the maximum total uniform load tables in the AISC manual. These tables are based on the moment capacity of the beam in which the max uniform load is “backed out” and the shear is determined. So these tables are based on the following: M=wL2/8 and since V=wL/2, then M=VL/4 or V=M/(L/4). Paradoxically, the longer the beam - the smaller the shear demands. Therefore, beams will have to be designed close to their flexural capacity for a connection to be reasonable. Figure 2 clearly describes the absurdity of this method. The shorter member requires much larger bolts and tabs, in addition to the welded doubler plate to meet the demand.

For composite beams, the EOR will add a multiplier of anywhere between 1.5 and 2.3 on top of this shear to account for the increased moment capacity due to composite action with the concrete slab. For cantilevers, the EOR should be careful because this method is inappropriate, since the maximum total uniform load tables are based on simple span and cantilevers are usually not governed by strength.

For the EOR, this is the simplest method, just a quick note on the drawing. The EOR knows that as long as the beam works in bending (often from their analysis model), the shear connection will work. So the connection is designed for the maximum load it can support. This is often very conservative and inapproiate. It is a very costly method for the owner and fabricator and always leads to larger connections than necessary.

Types and Capacity of Shear Connections

Type 1: Beam to Beam Connections

Generally beam–to-beam connections have at least a top cope. Therefore, the capacities are difficult to calculate (cope section, block shear, etc). These are the most common connection on a project, yet they are often deemed as insignificant and “simple”. This is not the case.

Another complexity is when double angles are required on a project. If all the bolts are shared on each side of the girder web, an erection bolt (or other aid) must be added to the connection to be able to build and meet OSHA requirements. This can lead to problems with fit up and erection sequencing.

The EOR may not realize this, but when requiring the use of double angles for beam-girder connections, it is forcing the detailer to add erection bolts and often to extend the connection angles. In addition, it may affect the erection sequence and force the erector to place the floor beams in a specific sequence. For example, in the case where beams of different depths frame on either side of a girder and share bolts, the deeper beam may have to be erected before the shallower beam on the opposite side of the girder web (so the lower bolts can serve as the erection aid). This can cause delays. A clever detailer will stagger the angles on each side of the same beam web such that either beam can be erected first, but these angles may not fit due to the greater web clearance height required.

An example of inefficient use of connection material is the use of double angles to connect light beams with thin webs. Using 5/16” thick angle legs on each side of a beam web when the web is only a quarter inch is wasteful, yet very common. Furthermore, for beams with weights less than 30plf, it is not the connection angles that control the capacity; it is usually the web in block shear, coped section, or shear rupture (or bolt shear). Therefore, it is the author’s opinion that the EOR should allow the fabricator the freedom to use shear tabs for these reasons. Please note, the bolts in Figure 3 do not need to be staggered for 4” angle legs. If not staggered, this connection will be easier to erect if the shop installs the bolts to the beam web such that the orientation of the tail end of the bolts never meet (spiral pattern in plan).

Type 2: Beam to Column Flange Connections

The simplest connection for an erector to a column flange is a shear tab as shown in Figure 4.

If double angles are used, it may be important to stagger the bolts in this configuration. For the erector to have access to the tails of the column bolts using the TC bolt gun, the tails will always be facing out. This could cause interference with the shop installed bolts on the beam when two tails are on the same side of the beam web. Therefore, the author stronger recommends shear double angle shear connections to column flanges have staggered bolts.

Type 3: Beam to Column Web Connections

Double angles are best for beam-to-column web connections. Erectors that like the use of TC bolts in the field do not like shear tabs since the column flange interferes with the bolt gun.

Key Takeaways for EOR

- If the EOR is not designing all the shear connections, then require calculations by a PE registered in the state of the project for all connections, including shear connections, to be submitted for approval (similar to all connections). Do not put a table indicating the number of bolts only without checking every limit state of every connection.

- Try to add shears to the plans (method 1) or provide good table (method 2) – do not use note about the uniform load table method (method 3).

- Do not require double angles when shear tabs work

- Let the fabricator and/or fabricator’s engineer select the type of shear connection. Shear tabs are generally preferred for beam-to-beam and beam-to-column flange connections.

- It is more efficient and cost effective for the fabricator to hire or staff an engineer to design connections specific to their shop and erection standards and practices (e.g. shop bolted, staggered bolts for double angle connections, shop standards for connection material, etc)