Location: Warren, RI

Client/Architect: The Design Initiative, Inc.

Engineer of Record: Structures Workshop, Inc.

Westport Residence

Location: Westport, MA

Client/Architect: Stack + Co.

Engineer of Record: Structures Workshop, Inc.

Brown University Warren Alpert Medical School

Location: Providence, RI

Client/Architect: Capco Steel Erection Company

Connection Engineer: Structures Workshop, Inc.

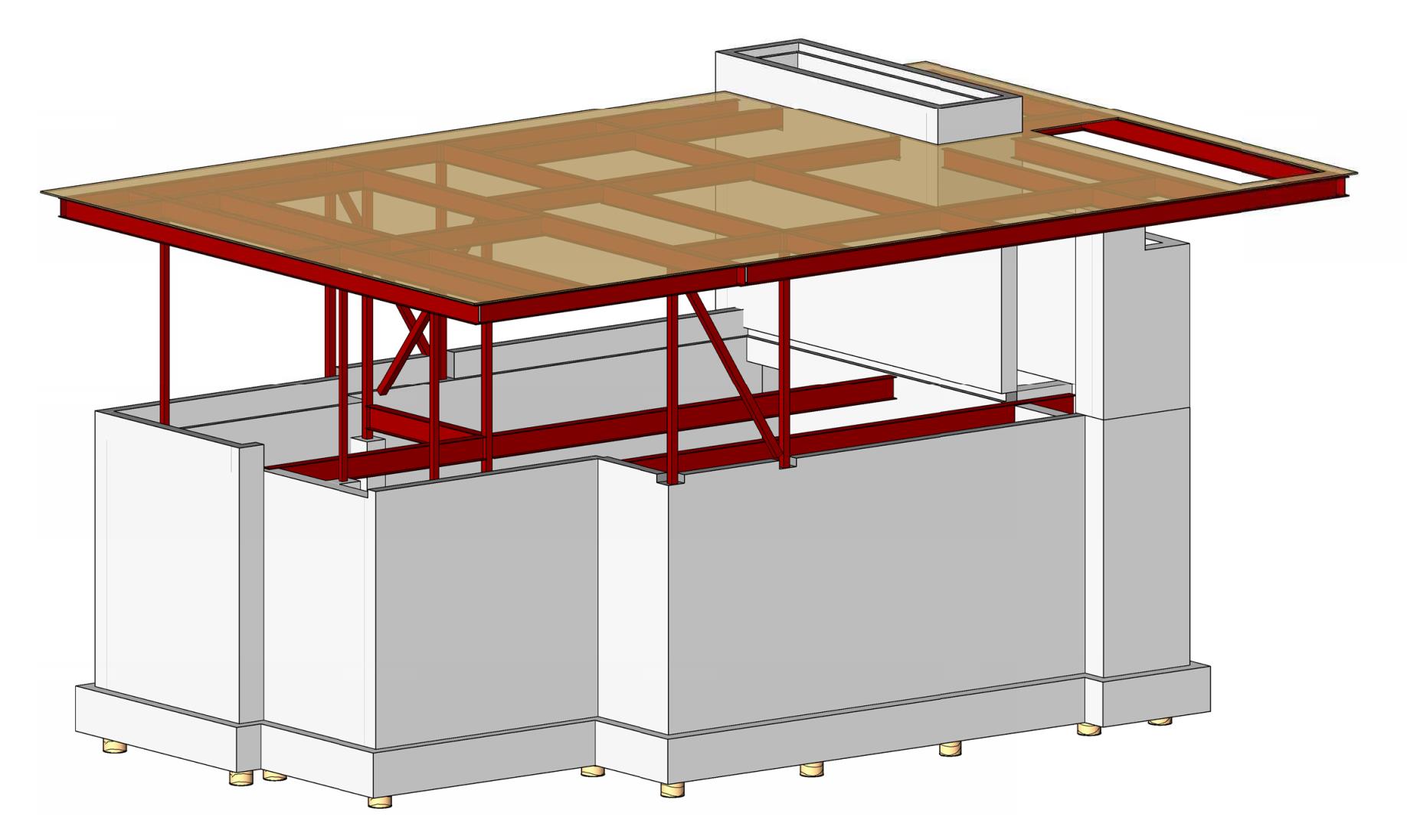

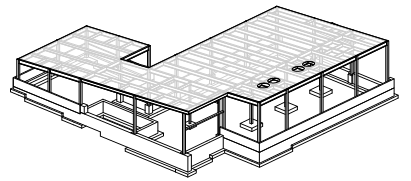

Queens Museum of Art Canopy

Location: New York, NY

Client/Architect: Capco Steel, M. Cohen and Sons

Engineer of Record: Structures Workshop, Inc.

Arch: Grimshaw Architects / Amman and Whitney

The design is a seamless stainless steel cantilevered frame with a 3/8 thick edge on all three sides. We were the structural engineers for the canopy and designed the canopy within a 1/16 edge tolerance by unhinging the stainless steel from the deflection of the carbon steel cantilevers. Some of our BIM model screen shots are shown.

The Big Hammock

Location: Boston, MA

Architect: Studio Luz

Engineer of Record: Structures Workshop, Inc.

DESCRIPTION

The second largest hammock on the planet. Designed with Studio Luz and RISD Students

Donation Type: Engineering Design Hours and Cash (Winner of Sept 1, 2010 award)

See http://thebighammock.org/

News: They’ve been swayed: Huge hammock rocks;Boston Globe 2010 08 19

Ben8qewu949Photography Shown Below: John Horner

Long Island Guest House

Location: Bridgehampton, NY

Client/Architect: Asher Israelow, Robert Highsmith, Stelle Lomont Rouhani Architects

Engineer of Record: Structures Workshop, Inc.

Standforville Barn

Location: Stanfordville, NY

Client/Architect: aardvarchitecture

Engineer of Record: Structures Workshop, Inc.

The barn structure consisted of heavy timber (Hemlock) post and beam frame with concealed metal fasteners combined with a dimensional lumber for the floor and exterior wall construction. The roof consisted of structural insulated panels (SIPs) designed to span between the master rafters. This project followed the integrated project delivery (IPD) approach with client and contractor input from the very beginning to the end. Our BIM model helped the contractor and design team verify quantities and coordinate methods of construction sequencing.

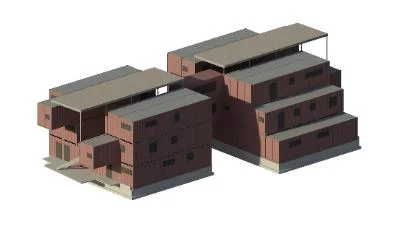

The Box Office

Location: Providence, RI

Client/Architect: Distill Studio

Engineer of Record: Structures Workshop, Inc.

The Box Office is a 3-story office building consisting of 32 reused shipping containers under construction in Providence. The office spaces contain dramatic 14 foot cantilevers and container bridges are formed to create passageways between office units. We created a robust Revit Container family for used section/detail creation.

SHIPPING CONTAINER ENGINEERING

A shipping container uses the full depth of the corrugated metal walls to span 40 feet (much like a wide flange beam needs it's web. It acts as a deep beam which is as deep as the height of the container. Therefore, structurally, these walls are very important to keep. To keep costs down, you want to let the container be a container; and try to keep the walls. Unfortunately that is often at odds with flexible space and leasing requirements of offices being a minimum of two containers wide. So some walls need to go. If the walls are fully or partially removed, the container becomes much more complicated. It can lose almost all of its stiffness and shear capacity. You need to introduce reinforcing (horizontal members or columns) because the small base channel cannot span very far in flexure. You can accommodate small window openings but determining size for unreinforced or minimally reinforced openings can be complicated. This is due to the walls having different properties in different directions - in the horizontal direction, the web is as flexible as an accordion - but in the vertical and shear orientation it is very stiff. There is additional complexity in determining how to economically reinforce modified containers - that is, how to minimize field welding and simplify the connections to adjoining containers and foundations. The container can be joined the same way they are stacked on a container ship, using steel assemblies that have manual levers to lock the containers together at each of the four corner castings. They may also need additional welded plates to tie them together horizontally. Given all the costly reinforcing required, the only way to make a shipping container building economical is very close collaboration with the owner, architect, and builder. This was the case on this project.

Queens Museum of Art Stair

Location: New York, NY

Client/Architect: Capco Steel, M. Cohen and Sons

Engineer of Record: Structures Workshop, Inc.

Arch: Grimshaw Architects / Amman and Whitney

Isle Brewers Guild

Location: Pawtucket, RI

Client/Architect: Ed Wojcik Architect Ltd.

Engineer of Record: Structures Workshop, Inc.

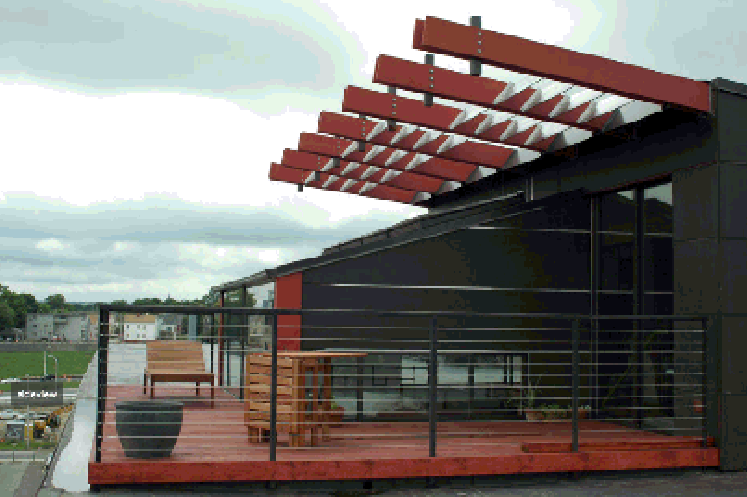

Walnut Hill Facilities Building

Location: Natick, MA

Client/Architect: designLAB architects

Engineer of Record: Structures Workshop, Inc.

Duxbury Crematory

ARCH: designLab Architects

ENG: Structures Workshop, Inc.

Design of a Crematory for the Town of Duxbury

SW # 10028

Imperial Place Addition

ARCH: From-In-Form

ENG: Structures Workshop, Inc.

LOC: Providence, RI

YR: 2008-2009

DESCRIPTION: Structural design of a one-story wood framed addition on top of a 6-story condominium. (SW# 08016)