Engineers Make and Fix Stuff

In order to answer, "What makes me an Engineer?" allow me to start with my childhood and reflect on key moments that led to my decision to go into engineering. I will later generalize to the type of person that typically enters this profession. When I was about three years old, my parents were concerned that I might be autistic because I did not talk. I struggled in social situations and preferred being on my own with building blocks or trucks. Anything with wheels or toys for building were the most appealing. I learned much later that I was considered a "non-verbal" thinker (more on that later). I did not do well in kindergarten or first grade and flunked second grade. I specifically remember my mom telling me that I was going to stay in second grade and my twin brother was going to advance to third grade. I was given speech therapy and slowly caught up to others my age, but it really was not until high school that I felt comfortable reading and comprehending words. What I lacked in social skills, writing, or reading was offset by considerable skill in making stuff. I built pretty amazing castles and boats out of wood blocks and LEGO bricks. While upbringing specifics will obviously vary from Engineer to Engineer, I have yet to meet one who wasn't master of LEGOS.

The first time that I heard about engineering was when I was about ten. My mother told me that I would be a good one after I had fixed the back door of our AstroVan. It had two doors that opened like a refrigerator. There was a nylon strap that got disconnected from a steel bar that prevented the door from swinging too far. After fixing this and hearing from my mom, I thought to myself that engineering must be an easy profession. I was also a sort of family mechanic, setting up the new VCR, fixing the phone, taking apart the sewing machine and putting it back together. Being mechanical takes curiosity to understand how something works, along with the trial-and-error method. It is not only curiosity, it is the will to do something without help. My Mom would read the manual on how to connect the VCR and then she would worry. I didn't read the instructions, I just tried different plugs. It was actually very simple.

As a sophomore in high school, I received an assignment to write and present on what I wanted to be when I grew up. I heard from others the typical white-collar professions such as doctors, lawyers, businessmen, politicians, etc. Surprising my teacher but not my family, I wanted to be a car mechanic. I wanted to understand the car engine. Being a car mechanic made sense and was exciting. I loved cars as a kid and still do; what could be more exciting than understanding the car engine and developing the skills to be able to fix it? I was always good at math and physics, but I did not want to do math and physics; I wanted to design and build real things. Math was like a fun puzzle similar to Sudoku, but it was not something that felt real or tangible.

In college, I continued to excel at math and physics, but I did not really enjoy sitting and solving homework problems. I was a math major but I expressed concern with my adviser after finishing a test on Abstract and Discrete Mathematics. "How does the idea of Infinity or Set Theory relate to real things of this world? Just refuting the non-existence of infinity, does not make infinity real? It is all in the mind. What is it exactly and where is it constructed in material reality?" He asked me what interested me and realized something more concrete and obviously pertaining to this world would be a better fit, specifically mentioning three options: architecture, structural engineering, and mechanical engineering. I changed schools and chose structural engineering.

My early path in life described above may or may not be similar to that of other engineers, but there are likely similarities in abilities. We all choose a profession that is grounded in material reality and has obvious meaning and importance to humanity. We are also good at building or making stuff, fixing things, and taking things apart and understanding them; but why is this?

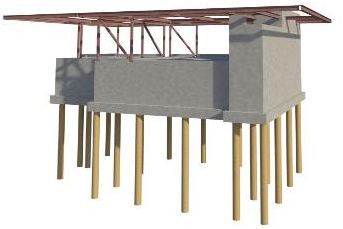

Lift House, Remove First Floor, Pour New Foundation

Engineering requires Competence/Proficiency, not "Intelligence"

In Jon Schmidt's excellent article "Contemplating Competence" in EOR Viewpoint (11/18/11), he describes how competence is based on skill acquisition, not attainment of information or classroom learning. Below he describes skill acquisition based on Drefus's phenomenological study:

Philosopher Hubert Dreyfus and his brother Stuart, an industrial engineer, conducted a phenomenological study of various "unstructured" problem areas, such as task environments that contain a potentially unlimited number of details that may or may not be pertinent. The resulting model of skill acquisition:

1. The "novice" complies with strict rules based on context-free features of the task environment.

2. The "advanced beginner" recognizes situational aspects of the task environment and follows maxims to adjust his or her actions accordingly.

3. The "competent performer" does not try to account for all discrete elements of the task environment; instead, he or she selects a plan, goal or perspective to establish which elements are relevant and which may be safely ignored.

4. The "proficient performer" no longer reflects on the task environment as a detached observer; without having to evaluate multiple options, he or she simply sees what needs to be done and then chooses how to go about doing it.

5. The "expert" intuitively perceives both what needs to be done and how to do it, making extremely subtle and refined discriminations in a variety of task environments that are sufficiently similar to those previously encountered. [Schmidt]

The higher levels are attained when one becomes an engineer, and that requires extensive experience working in the industry. Jon suggests these should become the standards for licensure (and perhaps they should). But I think what separates the competent from the expert is the ability to intuitively understand the problem, identify the solutions and decide on the best solution for the problem with little need to exhaustively analyze each possible solution. How can a test be structured to account for this design ability? (for another topic) Currently, in the United States, one is able to practice enigneering after four years of experience and passing two tests (EIT and PE test).

He goes on to say:

However, when confronted with an unfamiliar set of circumstances, even experts inevitably revert to the behaviors of novices and advanced beginners. They must fall back on rules and maxims because they lack the kind or amount of experience that would enable them to discern the appropriate course of action. [Schmidt]

So, engineering does not require intellegence in the normal sense of the word. It requires competence and proficiency. The best of us, the experts, are those who work intuitively and able to make refined discriminations based on past successes and failures in order to make the best design decisions. This is a combination of natural ability, education, and experience (I guess that is obvious).

Engineers are Visual Thinkers

We engineers are good at math, not necessarily because we are smart, but because we learned math differently others. Most of the population are verbal thinkers, but we are predominately visual. Visual thinkers can skip the reading in a physics textbook, focus on the figures and images, and then better understand the mathematical manipulations. Engineers do not memorize formulas, they internalize them and play with them by altering one variable in their heads. We can see a pendulum in our head while changing the length of the string. Then we can recognize that the period of a pendulum is independent of the mass and solely dependent on the length. We can see the formula and the swinging at the same time. This is very different from another student who might need to memorize the formula and be able to follow a procedure to solve a particular problem. Visual thinkers can have full intuitive understanding, which has obvious advantages over the verbal thinker in fields such as engineering. I suspect that some people do mathematic only by following procedures, while others really understand it by taking the concepts further beyond just following established procedures. When math becomes procedural, it becomes boring and uncreative. Those who claim that they are bad a math say so because they have trouble visualizing the representation of it. Engineers are able to visualize equations as physical representations within the mind.

Engineers are visual or non-verbal thinkers in general. Not only do we represent physics in our minds, we are also able rotate static objects to understand them better. Our engineering designs live in our minds a spatial objects and we can enter our projects whenever we demand. We certainly are not talking to ourselves, we are seeing the thing in our mind. In Eugene Ferguson's book, Engineering and the Mind's Eye (Ferguson 1992), he quotes Richard Feyman (1988) when he discovered the difference between a visual thinker from a verbal one:

I said, "Thinking is nothing more than talking to yourself."

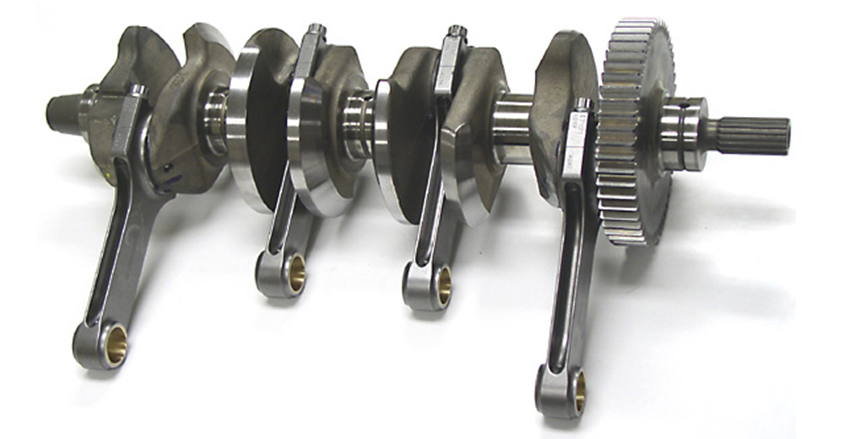

"Oh yeah", Bennie said, "Do you know the crazy shape of a crankshaft in a car?"

"Yeah, what of it?"

"Good. Now tell me: how did you describe it when you were talking to yourself?

So I learned from Bennie that thoughts can be visual as well as verbal.

Research by child development theorist Linda Kreger Silverman indicates that less than 30% of the population strongly uses visual/spatial thinking (Silverman 2001). According to Silverman (2001), "Visual/Spatial learning is the common phenomenon of thinking through visual processing using the part of the brain that is emotional and creative to organize information in an intuitive and simultaneous way." It is the ability to mentally manipulate two and dimensional figures in the brain. Engineers tend to be good at this.

Erik presents "El Linked Hybrid y mi Manifiesto para el Crecimiento" in Mexico

"Manifiesto para el Crecimiento" means “My Manifesto for Growth”. What this Manifesto means is really about how we as an engineering community (students, educators, and engineers) can grow as individuals and lead the profession into the future. How can we improve ourselves and therefore our profession. In so doing, we will improve our built world, and we will do this sustainably and honestly.

Here are some highlights of the 19 Ways to Grow...

6: Embrace Imperfection. If there is not a perfect solution, it follows that all solutions are not perfect. That means that there is always a better solution than the one you just submitted for construction.

7: Forget about Goals. We don’t know the end product, the final construction is unknown. So it is pretty reasonable to suggest that the goal of achieving this or that building is useless. How could something unknown obligate us?

8: Kick Ass. Cooperate, listen, be humble, but don’t let that prevent you from kicking ass.

The Steel Yard project wins ASLA Honor Award!

From the 2011 Professional Awards Jury:

“Sophisticated and visually rich. It truly broadens the definition on what can be beautiful. The landscape architects stayed true to its purpose. It feels so appropriate. Every sectional move is related to the ground conditions. It’s the next generation of Gasworks Park, it not only explains how they deal with post-industrial artifacts, but how they deal with sustainability. ” http://www.asla.org/2011awards/183.html

Architect: Klopfer Martin Design Group

Civil Engineering: Morris Beacon design

Structural Engineering: Structures Workshop, Inc.

Civil Engineering + Permitting: EA Engineering, Science & Technology

General Contractor: Catalano Construction

Landscape Contractor : MON

Artists for Humanity

Duxbury Steel Erected

60,000 Tons of Steel

Structures Workshop has completed over 100 steel connection engineering projects over the past 2 years amounting to over 60,000 tons of steel

Artists For Humanity Canopy is being Erected Today

Steel Yard on Cover of LAM

Our Box Office Project makes Front Page of Projo

Structures Workshop completed the design of the largest shipping container building (35) in the US and it made front page of the Providence Journal today. It was designed in 2009 and completed in 2010. Also see http://structuresworkshop.com/08035.html

Which part of Engineering is Offshorable?

Alan Blinder and Alan Kreuger's surveyAlternative Measures of Offshorability states the following:

Jobs that can be broken down into simple, routinizable tasks are easier to offshore than jobs requiring complex thinking, judgment, and human interaction. [Blinder/Krueger; 2009, 7]

Offshorability appears to be particularly prevalent in production work and in office and administrative jobs. By industry group, it is most common in manufacturing, finance and insurance, information services, and professional and technical services. More educated workers appear to hold somewhat more offshorable jobs. [Blinder/Krueger; 2009, 39]

So this begs the question, which part of my definition (see another post) of structural engineering is offshorable? I would venture to say it is the applied science, mathematics, and code verification portion (about 20% of what we do). Anything that can be done automatically from a computer is offshorable (analysis models, drafting, science, etc). Everything else (design) is not. That being said, I do not think analysis and drafting would be done well overseas without having an engineer or drafter within the locality of the project review the work. The local experience is invaluable in our field. For example, the outsourcing of steel drafting (called detailing) has become a major problem in the steel fabrication business. They charge very little overseas (detailers overseas charge $5-$30/ton as opposed to $60-$80/ton locally) but there are so many mistakes that can arise by using overseas detailers. The 20k savings of using an overseas detailer may end up costing the fabricator 40k in extra welding costs or mistakes in interpreting the AISC code.

Think about what a robot can do - that part of engineering is offfshorable. Engineering is a complex task that involves high levels of judgment and experience. It also involves human interactions (meeting with architects, site visits, working in collaborative teams, etc). None of this is offshorable. Our scientists and mathematicians may need to worry more about this issue than we do. The applied science or code procedure portion of what we do may be considered offshorable, is only 20% maximum of what we do. Our software will continue to do more and more code verification and analysis, but again that is still a small portion of our daily activities as an engineer.

As an example of why even the applied science portion cannot easily be done by a computer, see my article Twilight of the Idols. It compares a terrible floor system solution from a computer to a good floor system solution from an experienced engineer.

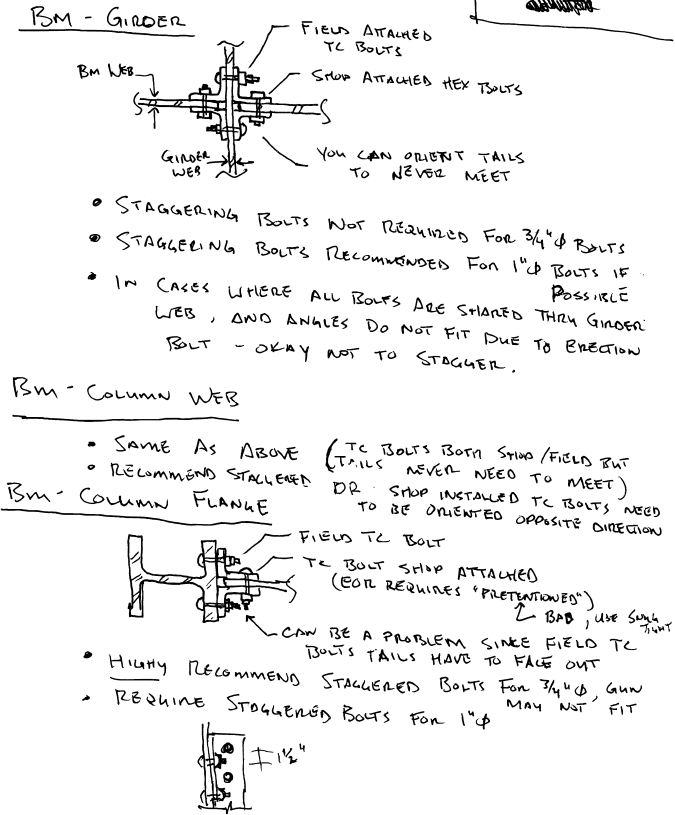

Bolt Clearance Issues

Erik invited speaker to EDIFICIA in Mexico

Erik will be heading to Monterrey, Mexico as an invited speaker at the EDIFICIA conference in early November at the Instituto Tecnológico y de Estudios Superiores de Monterrey (ITESM). ITESM is widely considered the largest and most prestigious private engineering university in Latin America. “EDIFICA 2011: XVIII International Civil Engineering Symposium” includes conferences and workshops to improve future Mexico’s infrastructure and structures and to promote sustainable building technologies. Erik will speak about new construction technologies using his projects such as the Linked Hybrid project, the Jinhua Pavilion , and the Box Office. He will also deliver portions of his Manifesto for Growth throughout his presentation.

The Design of Design!

Gordon Glegg's wonderful little book The Design of Design (1969) starts off with a bang. The brilliant mechanical engineer and author begins his book with:

An engineer has almost limitless possibilities. He can, and frequently does, create dozens of original designs and has the satisfaction of seeing them become working realities. He is a creative artist in a sense never known by the pure scientist. An engineer can make something. He creates by arranging in patterns the discoveries of science past and present, patterns designed to fit the evermore intricate world of industry. His material is profuse, his problems fascinating, and everything hinges on his personal ability. His successes and failures become incarnate in metal. They grow up and confront him, sometimes with surprising results. A scientist can discover a new star but he cannot make one. He would have to ask an engineer to do it for him. [Glegg, 1969:1]

Well done Gordon! Let's make a poster out of this. If we added this to our classroom doors or our workplace walls, we replace the tired notion that science is the most rewarding profession. Our high school students might embrace the engineering profession. Our college students might stay in the engineering major (the reality is 50% drop out). Our offices would surely benefit as well. Hmm, I better add this poster idea to my manifesto.

The American Engineer?

Billy Vaughn Coen states in "The Engineering Method" by (1984) that

Numerous studies show that the American Engineer is less well read, a better family member, more conservative politically, more oriented to the use of numbers than to general philosophical positions in making a decision, and goal oriented. [Coen, 1984]

My manifesto contained within this blog is partly a rebuke to this (except for the family part). It doesn't challenge the perception of who we are, but who we are. Presumptuous? Yes, of course, after all, I did write a manifesto. When writing it, I realize some things will come off as too simplistic and can be misleading. It is meant to be read as a coherent whole, not piecemeal. If I have offended anyone, I meant to, but not in the negative way. I hope I have positively offended you! Now please write back and offend me too at ean@structuresworkshop.com My intent is not to provoke, but to seek truth, to be clear, to translate what I do as an engineer (when designing buildings), as an educator, and as a citizen and human being. It shouldn't be provocative. In 20 years, this is all going to sound pretty straightforward and bland (this is not a goal, just a natural progression towards truth). Also, most these ideas are not mine, I steal them. Sometimes I don't always know where I steal them or from whom. I am sorry about that. I couldn't figure out where I got the idea that goals are unhealthy. That came from within - I am really excited about that one. The ideas about the design process were easy - I just looked at my sent items email folder for one day. I have read many of these ideas before but they are scattered and not coherent. That was why I decided to lay it all out. It is a draft, and my manifesto will always be a work in progress… towards quality- just like engineering.

Is Engineering closer to Art than to Science?

A quote taken from the "Historical Definition of Engineering" by Edwin Layton, Jr. (1984) contains the definition that engineering is the great creative science. A prominent civil engineer, Thomas C. Clarke, held that

Science is the discovery and classification of the laws of nature. Engineering, in the broadest sense, is the practical application of such discovered laws...engineering is the great creative science. [Layton, 1984]

This is better than we are applied scientists but it still puts too much emphasis on science. Edwin Layton agrees and states...

Engineering is a community of people who are practitioners of a creative form of cognition, engineering design, akin to that practiced by artists. [Layton, 1984]

Our method, the engineering method, is closer to how an artist goes about their work than it is to the scientific method. For more definitions of engineering that characterize it as an art, see Jon A. Schmidt's excellent article "Philosophy and Engineering" in Structure September 2008 issue.

Engineering is the Use of Engineering Heuristics

In "The Engineering Method" by Billy Vaughn Coen (1984), Coen states correctly that everything in engineering is heuristic. A heuristic is something that helps the engineer make a design choice.

The rule of engineering is: do what you think represents best practice at the time you must decide...the definition of the engineering method depends on the heuristic; the rule of the method and the rule of judgment are heuristics...all engineering is heuristic. [Coen, 1984]

Coen lists some sample heuristics such as:

- "Engineering is trial and error" or

- "Work at the margin of solvable problems" or

- "The yield strength of a material is equal to a 0.02 percent offset on the stress-strain curve"

This is what the engineer does, this is the engineering method. Engineering is the use of engineering heuristics. It is as simple (or complicated) as that. My problem with this definition is only the word "heuristic", it is too complicated. I think it should be called "design aids" or "engineering guides" to reveal a solution to an ill-defined problem (as opposed to well defined problems of applied science). So in this sense, engineering is a decision making process by an engineer who applies know-how and personal values (similar to my definition).

![LAM-steel-yard-cover[1]](http://static1.squarespace.com/static/5b50dee412b13f916dbf6993/5b64a7fce0c9380bf64954f1/5b64a801e0c9380bf64955c5/1533323265191/LAM-steel-yard-cover1.gif?format=original)